Medical 3D Printing that is simple, fast and cost effective.

MedFab3D is a FDA registered leading edge technology company that specializes in bringing Digital Fabrication technologies (3D Printing and Design) to the medical community. We lower the cost and complexity of implementing and managing additive manufacturing systems by using open source hardware, software and materials. Our systems allow us to take a clinical approach to delivering 3D printed medical products. We are registered with the FDA to produce casts, braces, splints and prosthetic components.

We are Medical Makers

A Maker is someone that uses their ability and knowledge to create. At MedFab3D we use our knowledge of digital design and manufacturing technologies to design and create products on demand for the medical community to improve patient outcomes. We make things that you are familiar with such as casts, braces and prosthetic components, better by using digital design and manufacturing technologies. These technologies allow customization and virtual evaluation of our products before manufacturing using information collected from the patient (pictures, x-rays etc..).

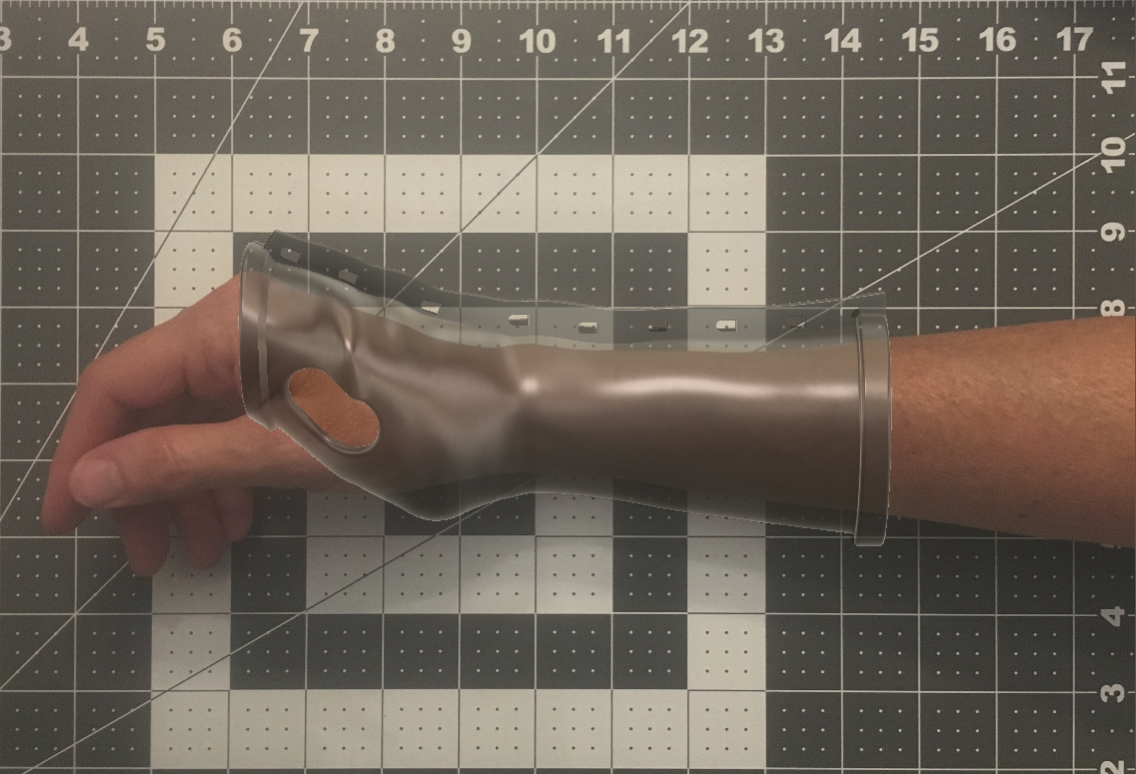

Digital design and fit evaluation of the EXO3D cast

EXO3D 3D Manufactured Cast

The Exo3D 3D printed cast is our first product in the additive manufacturing area. Our casts are custom fitted from parametric designs. The Exo3D cast can be fitted from a picture or an X-ray and manufactured within 24 hours. The focus of this product line is on the lower arm and we are looking to add other casts types over the next year including leg and foot casts that are non-weight bearing.

FDA Registered

EXO3D 3D Manufactured Cast

Open Source Hardware and Software

Autodesk Fusion 360 is used for the design of our products.

Marlin Open Source 3D Printer Control Systems